Acoustic Barriers: The Key to Effective Sound Insulation

Introduction

Acoustic barriers are vital tools in soundproofing and noise control. These specially designed products help mitigate unwanted noise by preventing sound transmission and reducing impact sounds. In various sectors like automotive, construction, and manufacturing, acoustic barriers are essential in maintaining comfort and safety by controlling noise pollution and improving the overall acoustic environment. In this article, we will explore the different types of acoustic barrier products, their applications, and the benefits of incorporating them into various industries.

What Are Acoustic Barriers?

Acoustic barriers, also known as sound-insulating products, are materials designed to reduce or prevent the transmission of sound. These barriers can either absorb or deflect sound waves, helping to maintain a quieter environment by preventing sound from traveling between spaces. The effectiveness of these barriers depends on the materials used, their thickness, and their density. Acoustic barriers are commonly used in industries where noise control is essential, such as in automotive manufacturing, construction, and machinery operations.

The primary goal of acoustic barriers is to limit sound transmission loss (STL), which is the reduction in sound intensity as it travels through a medium. Whether used in walls, ceilings, or machinery, these products are essential in minimizing noise disruptions in various applications.

Types of Acoustic Barrier Products

Acoustic barrier products come in various types, each designed to address specific noise control needs. Let’s look at some of the most common and effective options available.

1. Polymeric Acoustic Barriers

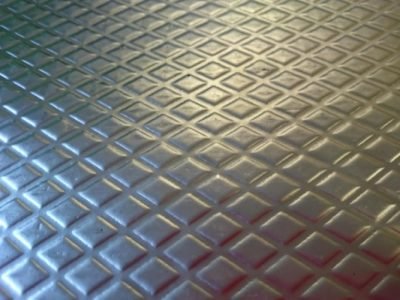

Polymeric acoustic barriers, such as the C03 and C09, are low-density vinyl membranes loaded with natural materials. These barriers are designed to improve the sound insulation of existing panels made from metal, wood, or plastic. By adding these barriers, the sound absorption capabilities of the original materials are enhanced, providing better soundproofing.

These polymeric barriers are particularly effective in overcoming coincidence dip resonance in lightweight composites like plywood and hollow core panels. Their ease of installation and compatibility with different substrates make them a popular choice for various applications.

2. Bitumen PE Foil Covered Acoustic Barriers

The C022 (3mm) and C023 (5mm) are bitumen-based acoustic barriers with a black PE foil covering. These products are known for their excellent sound insulation properties and vibration-dampening capabilities. The PE foil acts as a protective layer, preventing seepage from the bitumen and allowing for easy bonding with other substrates. These barriers are ideal for applications that require flat sound insulation, such as in automotive parts and industrial machinery.

3. Bitumen Aluminium Acoustic Barriers

For areas exposed to heat, bitumen aluminium acoustic barriers, such as the C024, are ideal. These barriers feature a laminated layer of bitumen, polymers, and mineral fillers, all protected by an aluminium foil. The dense structure of the C024 helps dampen sound, making it perfect for engine blocks in cars, construction vehicles, and agricultural machinery. This type of barrier is essential in high-temperature environments where both noise control and thermal resistance are necessary.

Applications of Acoustic Barriers

Acoustic barrier products are used across a wide range of industries, providing effective sound insulation and vibration control. Below are some of the key fields where acoustic barriers are commonly applied.

1. Automotive Industry

In the automotive sector, noise reduction is crucial for improving the driving experience and ensuring the comfort of passengers. Acoustic barriers are used in various car components, such as engine blocks, doors, and panels, to minimize road noise, engine noise, and vibration. By adding these barriers, manufacturers can improve the overall noise performance of vehicles, making them quieter and more comfortable.

2. White Goods and Home Appliances

White goods, such as refrigerators, washing machines, and dishwashers, can generate considerable noise during operation. Acoustic barriers help to dampen these sounds, ensuring that appliances run quietly and efficiently. These barriers can be applied to the internal panels of appliances to reduce operational noise and vibration, contributing to a more peaceful living environment.

3. Lift Cabins

Acoustic barriers are also commonly used in lift cabins to reduce the noise generated by the movement of the elevator. By applying sound-insulating materials to the walls and floors of the cabin, the noise of the machinery and movement can be significantly reduced, providing a more comfortable experience for passengers.

4. Construction Vehicles and Agricultural Equipment

Construction vehicles and agricultural machinery often operate in noisy environments. Acoustic barriers are used in the cabins and engine areas of these vehicles to reduce noise exposure for operators. This helps create a safer and more comfortable work environment, reducing the risks associated with prolonged noise exposure.

5. Pipe Insulation

In industrial settings, acoustic barriers are often combined with pipe insulation to reduce the noise generated by fluid flow. This is particularly important in large-scale facilities where loud noises from pipelines can cause disruptions or even hearing damage. Acoustic barriers help mitigate these sounds by providing a layer of soundproofing around the pipes.

Benefits of Acoustic Barrier Products

Acoustic barrier products offer a range of benefits across different industries. By incorporating these barriers into machinery, vehicles, and buildings, companies can achieve significant improvements in noise control and vibration dampening.

1. Reduced Noise Pollution

One of the primary benefits of acoustic barriers is the reduction of noise pollution. In industries like automotive and construction, noise can be a significant source of disturbance. Acoustic barriers help mitigate the transmission of sound, making workplaces and living environments quieter and more pleasant.

2. Enhanced Comfort and Safety

In environments where noise levels can be hazardous to health, such as in manufacturing plants or vehicle cabins, acoustic barriers play a critical role in maintaining comfort and safety. By reducing exposure to loud sounds, these barriers help prevent hearing damage and create a more conducive work environment.

3. Vibration Dampening

Acoustic barriers are also effective in reducing vibrations caused by machinery and heavy equipment. These vibrations can lead to structural damage over time and contribute to noise pollution. Acoustic barriers with vibration-dampening properties can significantly reduce these effects, prolonging the life of equipment and structures.

4. Energy Efficiency

In some applications, acoustic barriers also serve a dual purpose by providing thermal insulation. This is particularly useful in environments where temperature control is critical, such as in automotive manufacturing or HVAC systems. By reflecting thermal radiation, acoustic barriers help improve energy efficiency, making systems more effective and reducing operational costs.

5. Versatility and Customization

Acoustic barriers are highly versatile and can be tailored to meet specific needs. Whether it’s cutting barriers to fit curved surfaces or combining them with acoustic foams for enhanced performance, these products can be customized for a wide range of applications. Their flexibility makes them ideal for various industries, from automotive to construction.

Read Also: The Ultimate Guide to Using Instagram for Small Businesses

Conclusion

Acoustic barriers are a crucial component in the fight against noise pollution. By using high-quality barrier products, industries can significantly reduce noise transmission, enhance comfort, and improve the safety of their operations. Whether you’re in automotive manufacturing, construction, or any other sector dealing with excessive noise, incorporating acoustic barriers into your processes will provide long-term benefits. With various options available, including polymeric, bitumen-based, and aluminum barriers, there is a solution to suit every need.

For optimal soundproofing results, combining acoustic barriers with other materials, such as acoustic foams, can further enhance noise control. By working with reputable manufacturers and suppliers like Acoustafoam, businesses can ensure they have the right products to meet their specific requirements. Don’t hesitate to get in touch with experts to find the best acoustic barrier products for your industry.