Investing Smart in a cnc milling machine for sale

For manufacturers, prototyping firms, metal workshops, and even engineering institutions, CNC milling machines have become essential for maintaining speed, accuracy, and repeatability. Whether you’re launching a small machining shop or expanding an industrial-scale factory, finding the right cnc milling machine for sale can open doors to greater efficiency and product quality.

This article explores everything a buyer needs to know when seeking a cnc milling machine for sale—including its functions, types, features to evaluate, where to buy, and tips to ensure you make the best investment.

What is a CNC Milling Machine?

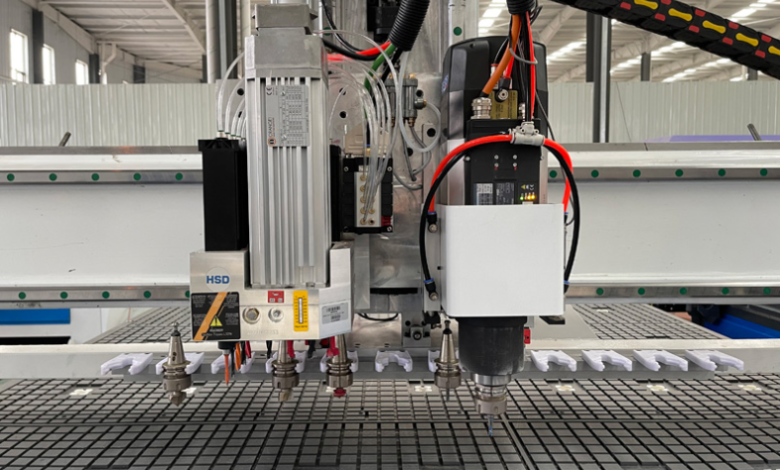

A CNC (Computer Numerical Control) milling machine is a programmable machine that uses rotary cutting tools to remove material from a workpiece. It follows coded instructions—typically generated through CAD and CAM software—to shape metals, plastics, or composites into precise components.

Unlike traditional milling machines operated manually, CNC milling machines work with digital precision and require little to no manual intervention once the program is set. This results in better speed, tighter tolerances, and unmatched repeatability.

Why Look for a cnc milling machine for sale?

Buying a cnc milling machine for sale is a smart way to:

- Cut Costs: Pre-owned machines or promotional sales allow businesses to access high-end equipment at lower prices.

- Expand Capacity: A second or third milling machine can help scale your business and meet larger orders.

- Start Prototyping In-House: Ideal for designers and startups who want control over their product development process.

- Modernize Production: Upgrading to CNC from manual machining boosts accuracy, consistency, and efficiency.

From low-volume custom orders to mass production runs, a CNC milling machine can fit the needs of a wide range of industries.

Common Applications of CNC Milling

Before diving into the specifics of selecting a CNC milling machine for sale it’s important to understand its wide-ranging applications:

- Aerospace: Machining complex parts like brackets, wing ribs, and fuel system components.

- Automotive: Manufacturing engine blocks, gear housings, and other precision parts.

- Medical: Producing implants, surgical tools, and lab instruments.

- Electronics: Creating precise housings and components for circuit boards.

- Tool and Die Making: Milling dies, molds, and custom jigs.

The flexibility of CNC milling makes it a top choice across industries that demand intricate designs and tight tolerances.

See also: How AI Face Swap Technology Is Shaping Influencer Marketing

Types of CNC Milling Machines Available

When you search for a cnc milling machine for sale, you’ll likely encounter these main types:

1. Vertical Milling Machines (VMCs)

These are the most common and budget-friendly options. Their vertically oriented spindles are great for face milling, end milling, and boring operations. Ideal for small to medium production volumes.

2. Horizontal Milling Machines (HMCs)

With a horizontal spindle orientation, HMCs are suitable for deep cuts and large-scale production. Their ability to handle bigger parts makes them popular in heavy industries.

3. 5-Axis CNC Mills

These high-end machines allow simultaneous movement along five axes, enabling the creation of complex parts in a single setup. Commonly used in aerospace, mold-making, and high-precision sectors.

4. Benchtop or Desktop CNC Mills

Perfect for DIYers, schools, and small-scale prototyping. Compact, affordable, and good for light-duty work.

Key Features to Look for in a cnc milling machine for sale

When evaluating a CNC mill, focus on these essential factors:

• Spindle Power and Speed

Higher spindle speeds are great for fine finishes and soft materials, while more powerful spindles are better for cutting hard metals. Choose based on your material needs.

• Build Quality

Stability and durability come from heavy-duty frames, often made of cast iron or steel. Rigid machines offer better accuracy and less vibration.

• Axis Travel

This refers to the range of movement along the X, Y, and Z axes. Make sure it accommodates your largest part sizes.

• Automatic Tool Changer (ATC)

An ATC enables the machine to switch between different tools automatically, saving time and allowing for complex multi-step processes.

• Control System

Ensure the machine runs on a reliable control interface like FANUC, Siemens, or Mach3. Some brands have proprietary controllers, which can either help or hinder usability, depending on your experience level.

• Software Compatibility

Confirm that the machine is compatible with the CAM software you already use (like Fusion 360, SolidWorks, or Mastercam) for smoother integration.

• Coolant and Chip Management

Built-in coolant systems extend tool life and improve surface finish. Chip conveyors help maintain a clean workspace.

New vs. Used CNC Milling Machines

When browsing listings for a cnc milling machine for sale, you’ll come across both new and used options.

✅ New Machines

- Come with full warranties

- Include the latest features and controls

- Require less initial maintenance

✅ Used Machines

- Offer significant cost savings

- May include upgrades or tooling from previous owners

- Can be just as reliable with proper maintenance history

Tip: If purchasing a used CNC milling machine, inspect the spindle hours, maintenance records, and software version. Always ask for a demonstration or test cut.

Best Places to Find a cnc milling machine for sale

If you’re ready to purchase, here are the top places to look:

- Manufacturer Direct: Trusted companies like Haas, Mazak, DMG Mori, and Tormach offer machines with service packages.

- Online Marketplaces: Websites like Alibaba, eBay, and MachineTools.com list thousands of new and used CNC machines from global sellers.

- Industrial Auctions: Liquidation sales are a great source of discounted machinery from downsized or closed facilities.

- Local Dealers: Certified dealers often offer inspection services, financing options, and installation support.

Trusted CNC Machine Brands

Brand reputation matters when you’re looking for a long-term investment. Here are a few respected names:

- Haas Automation – User-friendly and popular in the U.S. with solid after-sales support.

- Mazak – High-performance Japanese machines known for durability.

- Tormach – Cost-effective models for startups and light-duty use.

- Okuma – Excellent for heavy industrial applications with advanced software features.

- DMG Mori – German/Japanese engineering at its finest.

Each of these brands offers various models suited to different budgets and industries.

Key Questions Before Buying

Before finalizing your purchase, ask the seller:

- What’s the total number of spindle hours?

- Are there any known mechanical issues?

- What tooling or accessories are included?

- Is shipping and installation included?

- Is there a return or warranty policy?

These questions help you avoid costly surprises and ensure you get the best value from the cnc milling machine for sale.

Final Thoughts

Finding a reliable cnc milling machine for sale requires careful consideration of your production needs, available budget, and long-term goals. Whether you choose a brand-new 5-axis machine or a well-maintained pre-owned model, owning your own CNC equipment empowers your business with speed, precision, and flexibility.

The decision to invest in CNC technology isn’t just about buying a machine—it’s about future-proofing your operation, impressing your clients with accuracy, and gaining full control over your production timelines.